Ice Cream Technology

Firstly, the core ingredients (milk, sugar, dairy or vegetable fat, water and any minor components such as stabilizers) are mixed together and blended in a well stirred mixing tank. This first operation makes sure that a uniform mixture of the right ingredients in the correct proportions is created and that any powders used are properly hydrated.

Firstly, the core ingredients (milk, sugar, dairy or vegetable fat, water and any minor components such as stabilizers) are mixed together and blended in a well stirred mixing tank. This first operation makes sure that a uniform mixture of the right ingredients in the correct proportions is created and that any powders used are properly hydrated.

After mixing, the ice cream mix is pumped into a pasteurizer where it is heated rapidly to a predetermined temperature and held at this temperature for the appropriate length of time so that the microbiological quality of the final product can be guaranteed.

After pasteurization, the mix is homogenized by forcing the mixture of oil and water through a narrow slit at high pressure which causes the oil droplets to break up and creates a very fine dispersion. Typically, the average oil droplet size generated is less than one thousandth of a millimeter and these small drops reduce the tendency of the oil and water phase to separate.

After homogenization, the mix is cooled to a temperature of approximately +5 degrees Celsius in a heat exchanger. After cooling, the mix is stored at this low temperature and aged, normally for a period of a few hours. It is essential that ageing is long enough to allow the millions of individual oil droplets to partially solidify and allow the proteins to coat the surface of the oil. At this stage, it is also possible to add any heat sensitive ingredients such as colours, flavours and fruit preparations.

Finally, the ice cream mix is now ready for freezing! An ice cream freezer must aerate the mix, freeze it, and generate the characteristic texture of ice cream. Most commercial ice cream freezers operate in a similar way. The mix is pumped into a metal barrel which is surrounded by a very cold refrigerant. At the same time, a stream of air is introduced into the barrel. On the inside of the barrel, a “dasher” rotates at high speed and scrapes frozen mix from the barrel wall and mixes it back into the bulk of the mix. This ice formation, together with churning of the fat and breakup of the air stream into fine air bubbles transforms the liquid mix into ice cream. This freezing process has been fine-tuned over many years and fully automated computer controlled freezers capable of producing thousands of tubs an hour is available commercially.

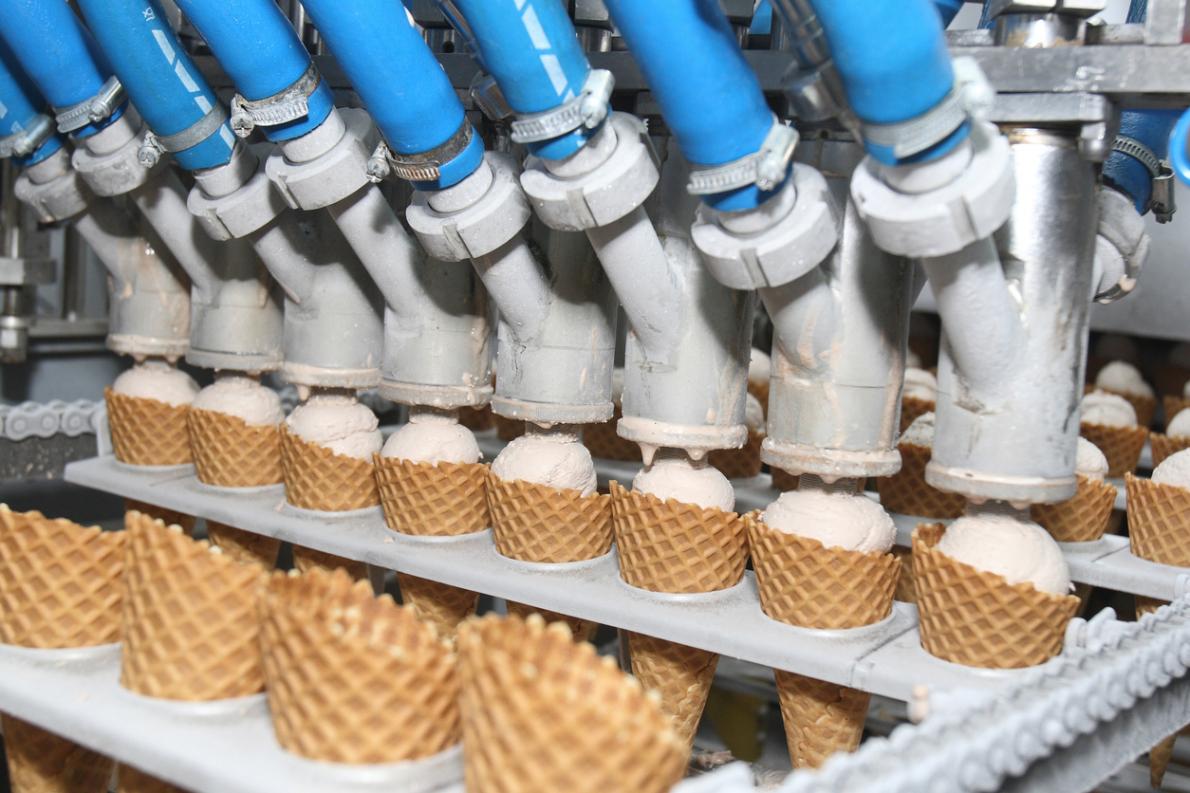

On exiting the ice cream freezer, the product can be filled directly into tubs or other packaging, combined with other ingredients such as nuts, sauces or chocolate or extruded into a variety of different shapes and formats.

The final step in ice cream manufacture is the process of hardening, where the freezing of ice cream is completed. Here the products are passed through a tunnel which operates at temperatures around -30°C and are completely frozen. This final freezing step stabilizes the ice cream structure and ensures that the small ice crystals and air bubbles do not grow.

Put very simply: Small ice crystals and small air bubbles give the creamiest ice creams!